Project brief

Noah is a cross-body fishing bag which fulfills all the needs of a fisherman - from posture shifting to versatile carrying and smart storage. Best of all, Noah is also able to splash fashion to your fishing adventure.

Tools

Team

Photoshop, Illustrator, Rhino, Sketch, CAD, 3D print

Delivered

Personal project

Timeline: 3 months

Year: Fall 2018

Primary and Secondary Research, Sketch, Storyboard, Ideation, Physical modeling, Fabrication.

How much will an ergonomically-crafted, all-in-one wearable fishing bag transform fishing experience?

Problem

The story started from a time I went fishing with my friend on a whim. My friend Jack is a hobbyist for fishing. During preparation, I surprisingly found out Jack tended to pack his gears and personal items into lots of one-off bags. "It's cheap and convenient enough." Jack answered. "Downside is always messy and hard time to find things at the very second." Jack's line made me thinking about a product blank to fill, which would leverage fishing experience for fishing amateurs with a big that is convenient and at a good price.

After close observations, I listed some design challenges that this product needs to solve.

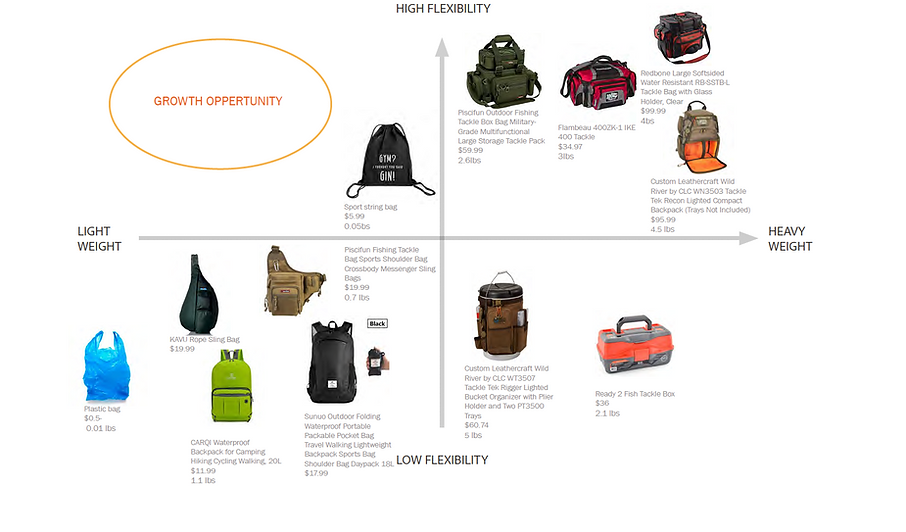

Market research

A competitive product matrix was made to help me further define product opportunity, competitions and trends in the current market.

Interview

I got back to the river and conducted interview to the fisher men. During this step, my goal was to broadly hear from their sides in order to understand expectations, values and pain points first-hand. I interviewed 4 amateur fisher men in total.

As I foresee the difficult to ask for a paper survey, plus the desire to get answers at the very scenario, ( while fishing.) I performed the survey verbally and took notes of answers during the interim of fishing.

I summarized the result of this interview below.

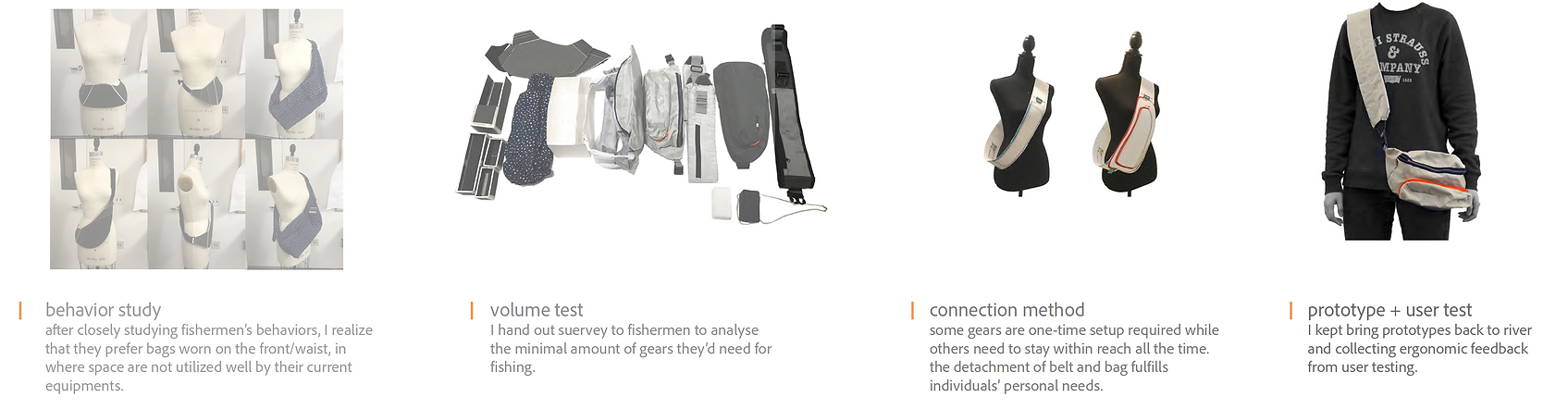

Prototype + Usability testing

During the previous interview, one man brought up that beginners usually carry redundant gears, which add a lot of weight. Thus I started off studying the expected volumeI of the bag. Then I made card board and fabric models to explore portion, position and compartments. In the mean while, I kept bring prototypes back to fisher men, and revise based on feedback I heard.

Photo of Jack testing on this early phase prototype.

From behavioral study I learned that most of the gears are used only during the preparation. When things are set up, fisher men would only keep very limited gears in reach like lure, web and scissors. People also expect backpacks that can be transformed/ detached into smaller size when they start staying immobile.

Based on the test feedback, I decided to take apart one piece to an attachable bag with a belt.

In later prototype, the major challenge was to attach the belt and the bag to maximize accessibility and flexibility on all the compartments.

Ideation

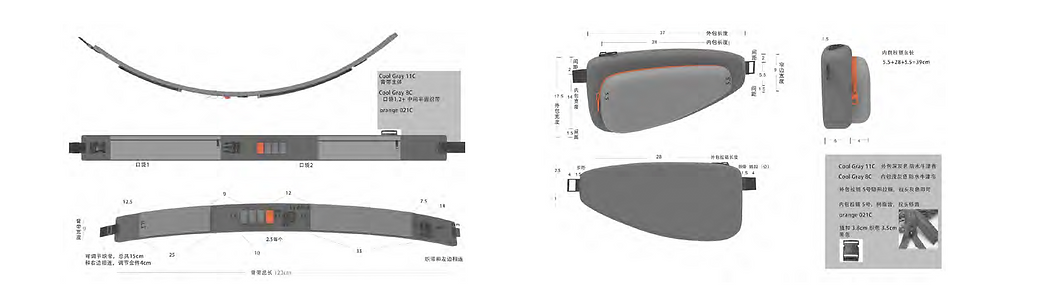

CMF consideration

I went to fabric outlets to study nylon and oxford fabric in different density. After taking durability, flexibility and fashion into consideration, I came out with a CMF instruction.

CAD communication

CAD model and rendering to communicate with Chinese manufacture. I marked out material and specification for every single part.

Production

I flew to Shenzhen, China to communicate with pattern tailor and supervised the first version sample. After usability testing, I revised inner, accessories, and width of the belt to make Noah, the fishing bag more ergonomic.

Second version of Noah and its package.